A combination of CHM spare parts and OEM

supporting leading enterprise GLORY create a series of brake pads have

been on the market !

1.Factory background

GLORY is currently the only domestic brake company to enterthe foreign brake supporting system

The main engine supporting business has a history of 25years, and has been successfully supporting many local brands such as GreatWall automobile, trumpchi, Shanghaiautomobile, JMC automobile, JAC automobile, etc., and is being introduced intothe international brand whole car factory Daimler Benz , Volkswagen, PSA andother projects

It is the first and only domestic friction materialsupplier that has passed ZF-TRW (Top international brake manufacturer) certification and entered its supportingsystem

Global top auto parts supplier supply experience: Boschbrake block local supplier, supply 17 years;Supporting mass production ofpassenger car main engine project in mainland Germany;ZF-TRW trina in 2014 mass production, and into themercedes-benz (under development) supply system

11 platform test equipment of the companycan detect brake pad products of various transportation tools and workingconditions, including passenger cars, operating cars, buses, light rail, etc.,and mark:

QC/T 564/479/237;JASO 406/407;

Q/19S 002; DT6C01 24/29; SAE 2681; DCACB027;

TL-110; JX14020;AK-Master (SAE2522); AMS;

HFT; Block wear;Krauss; Static Mu;

SAE J2521.

2.CHM brake pad series features:

Restorethe original brake pad brake feeling, fully ensure the compatibility of thevehicle, achieve the best comprehensive performance of the brake.As far aspossible to meet all kinds of operating conditions compatibility requirements,market expansion cost-effective demand

Disc brake pad

According to the different use of the car to fit the mostappropriate formula

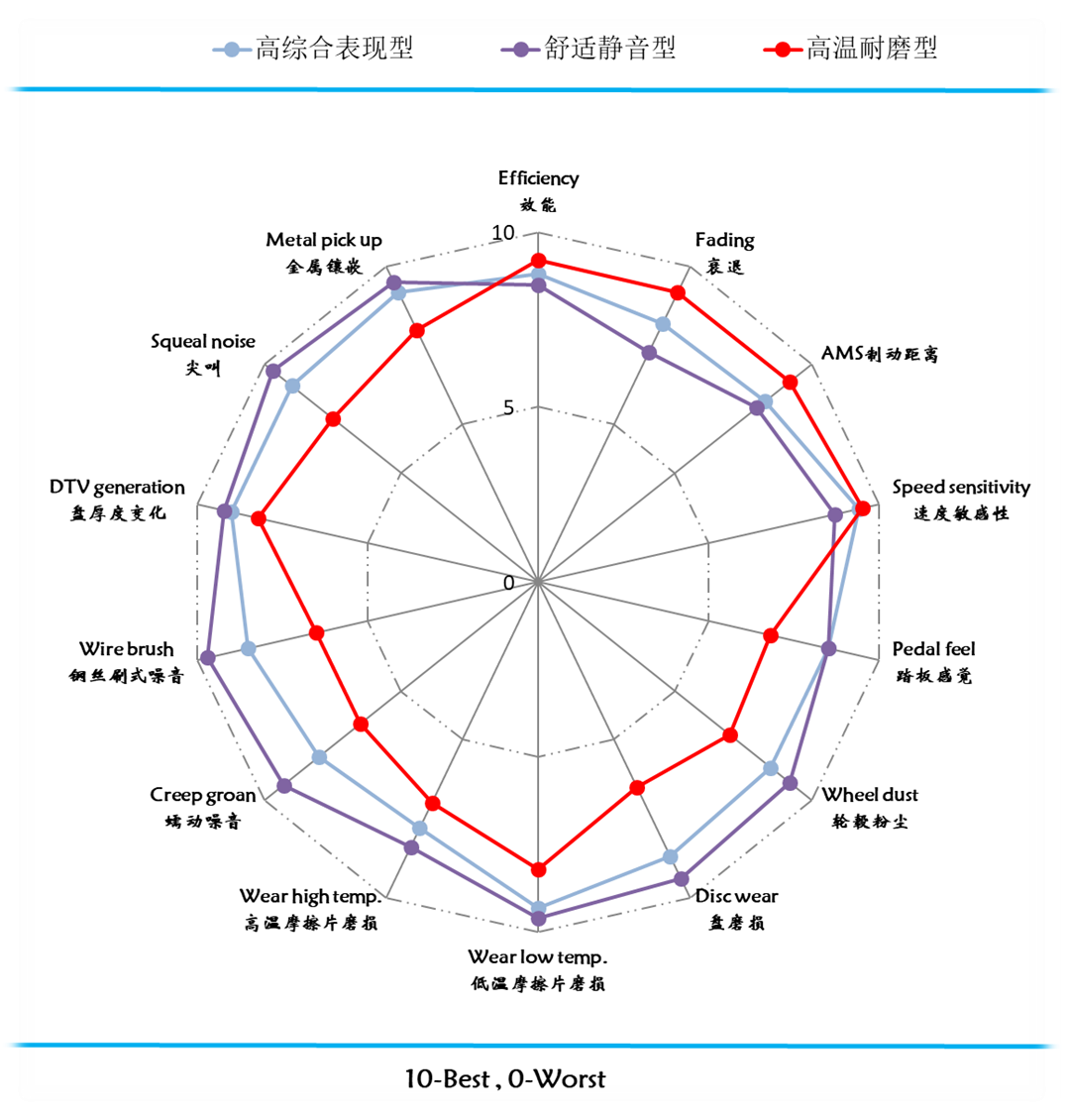

High comprehensive performance ceramic formula: at the sametime with high braking force and excellent noise performance, brake response issensitive, the brake disc damage is small, clean, especially suitable forEuropean cars, off-road vehicles

Comfortable silent ceramic formula: for solving noiseproblems and cleaning problems, braking performance and service life ismoderate, smooth, cost-effective, suitable for Japanese, Korean, Americanseries of models

High temperature wear-resisting metal formula: payattention to high temperature wear-resisting performance, highlight brakingforce and safety performance, have a longer service life, suitable for allkinds of operating vehicles, mountainous areas, car price less than 100,000vehicles

High comprehensive phenotype ceramic formulation

NAO ceramic formula, with Japanese ceramic technology asthe core, combined with China's national conditions to meet passenger vehicles,the pursuit of comprehensive performance of customers, SUV use developed, isthe latest generation of NAO formula.

High comprehensive phenotype formula adopts asbestos freematerial, with red copper, aramid, ceramic fiber as the main reinforcement, avariety of abrasive match

Special point

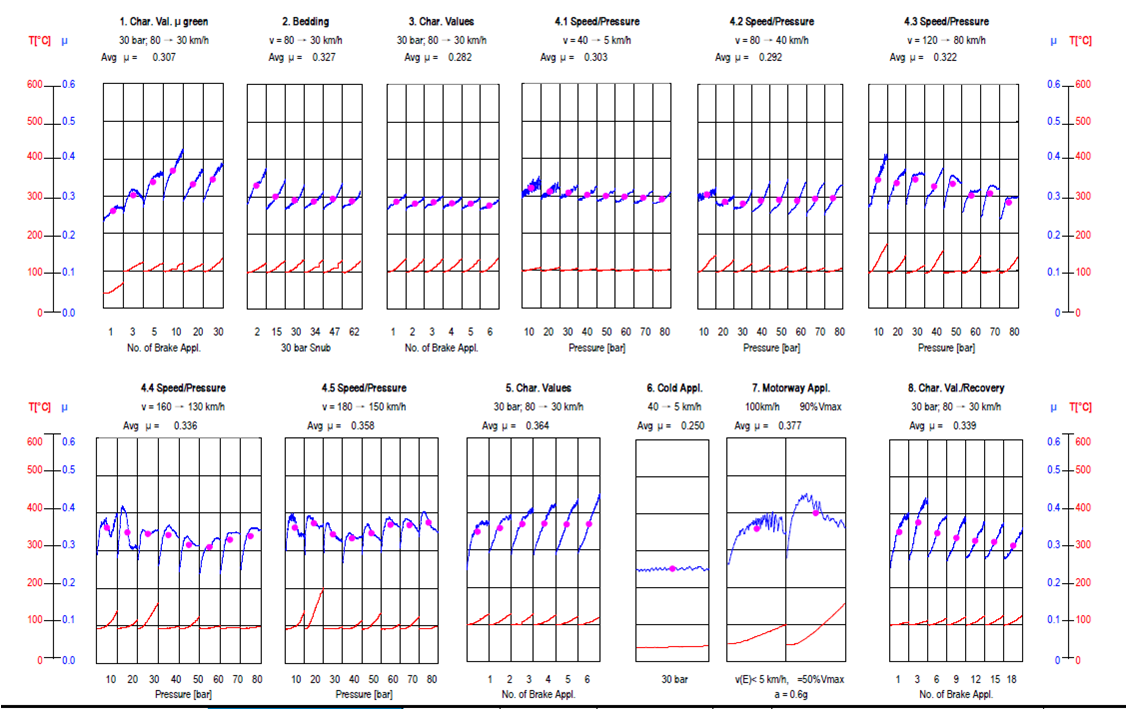

1. Stable friction performance, stable friction performanceunder various braking pressures and braking speeds;

2.100% noise reduction process: mute ceramic formula,product surface treatment

3. Compatibility: according to the formula of the vehicle,give consideration to braking power and comfort

4. High temperature resistance: 650 degree stable braking,high temperature long service life

5. Environmental protection materials: do not damage disc,do not drop ash

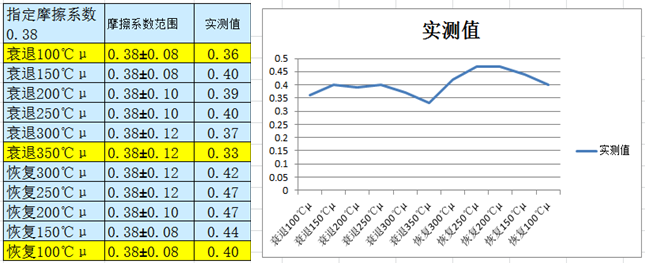

Friction coefficient test (GB5763-2008,Friction coefficient specified is 0.41, which meets the national standardrequirements) :

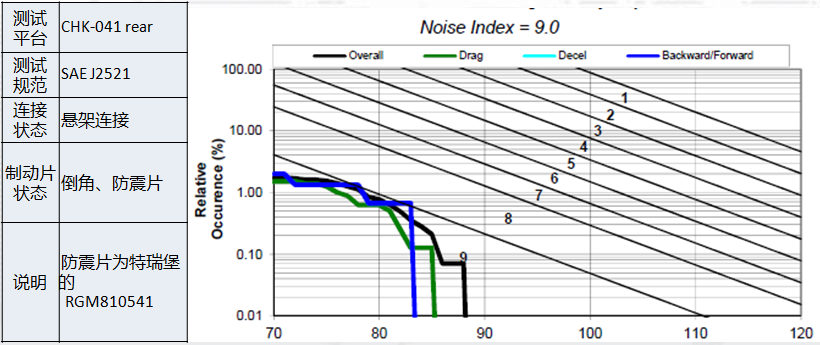

Noise performance (chamfer +SHIM) score 9.5:

CHM high comprehensive phenotype

Ceramic brake pads recommended reasons

The formula with high comprehensive performance isapplicable to disc brakes of after-sales passenger cars, which has obviouseffect on reducing brake block noise of disc brakes of Japanese and Koreanvehicles

Stable friction coefficient, low noise, good wheelcleanliness, comfort and other characteristics

After the successful application of internationalafter-sales market, domestic after-sales market, is a new generation of NAOleading formula.Can be used for family cars, urban SUV and the pursuit of highcomprehensive performance of the owner

Comfortable silent ceramic formula

Ceramic formulation with medium frictioncoefficient.The formula adopts red copper, aramid, ceramic fiber as thereinforcing main body, no asbestos

Special point:

1. Pay attention to wear resistance at high temperature,highlight braking force and safety performance, excellent friction coefficient,friction coefficient is 0.35, in a variety of braking pressure, braking speedhave high and stable friction performance, deviation in 0.05~0.10

2. Low wear.In the process of use, due to a more appropriatefriction coefficient, not only friction material itself wear is lower, and onthe brake dual wear is also lower, at the same time to avoid the phenomenon ofscraping disc, good hub cleaning

3. Low noise, ak-master formula performance

Friction coefficient test

Noise performance (chamfer +SHIM) score 9.0:

Comfortable silent ceramic formula

Ceramic formulation with medium frictioncoefficient.The formula adopts red copper, aramid, ceramic fiber as thereinforcing main body, no asbestos

Special point

1. Pay attention to wear resistance at high temperature,highlight braking force and safety performance, excellent friction coefficient,friction coefficient is 0.35, in a variety of braking pressure, braking speedhave high and stable friction performance, deviation in 0.05~0.10

2. Low wear.In the process of use, due to a more appropriatefriction coefficient, not only friction material itself wear is lower, and onthe brake dual wear is also lower, at the same time to avoid the phenomenon ofscraping disc, good hub cleaning

3. Low noise, ak-master formula performance

CHM high temperature wear resistant metal formula

Recommended reasons:

The wear of friction materials is lower at differentbraking temperatures

The wear of the formula material on the brake disc isobviously reduced (even with the phenomenon of thickening, the surface of thebrake disc is smooth after the test, and the transfer film appears on thesurface of the brake disc), which indicates that the attack of the brake discon the brake disc is obviously weakened, which can effectively avoid theoccurrence of MPU.

In North America and domestic has been a large number ofapplications, market response excellent

Drum type

CHM brake pad and CACaccessory products are produced in the same line, using the same formula.

Special point

1. Stable friction performance under various brakingpressures and braking speeds

2. Moderate braking performance and service life, goodsmoothness and high cost performance, suitable for Japanese, Korean andAmerican series models

3.100% noise reduction process: product surface treatment

4. Environmental protection materials: do not damage disc, donot drop ash

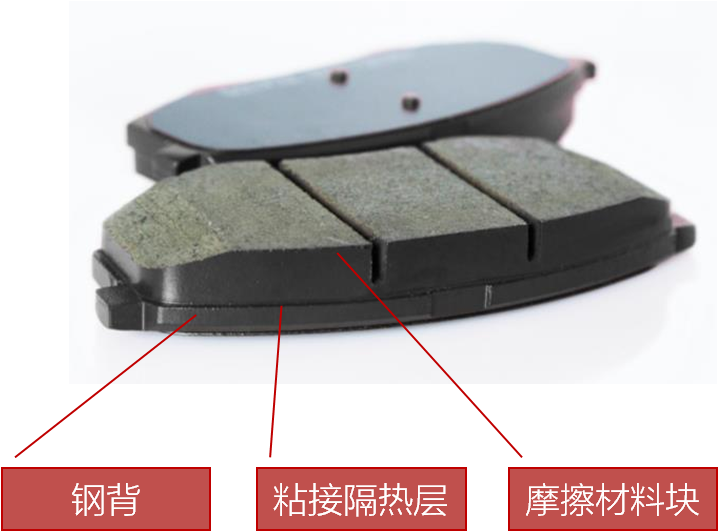

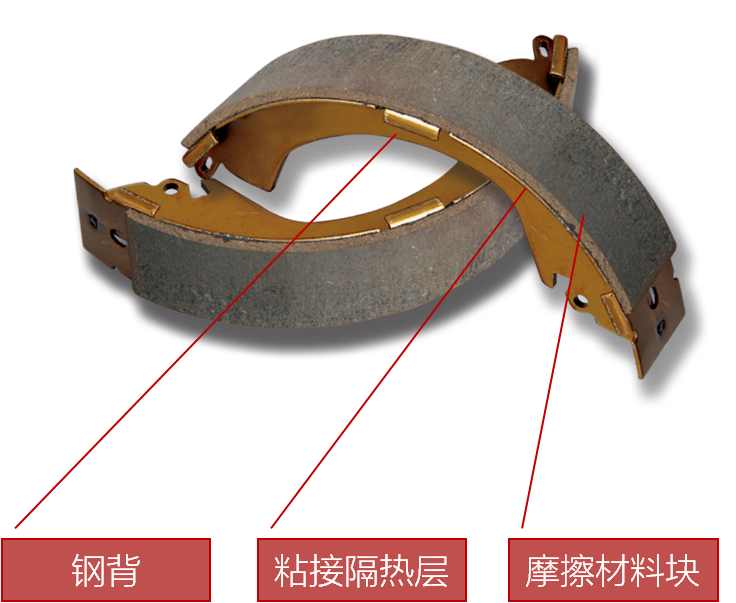

3. Brake pad basic knowledge

Divideclass

Brakelining is generally made up of a steel back, a bonded insulation layer, andfriction blocks. The key component is the friction material, which is squeezedagainst the brake disc or drum during braking, thus achieving the purpose ofdeceleration and braking

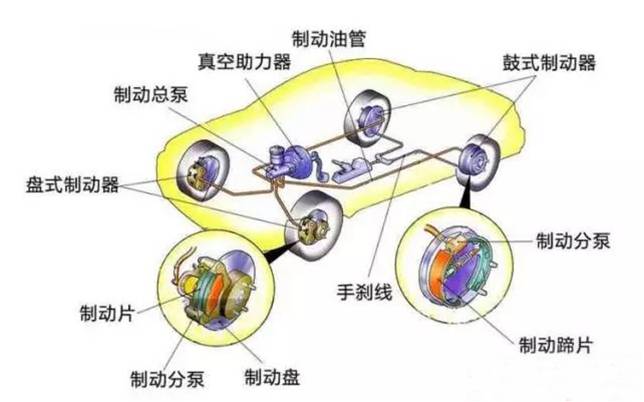

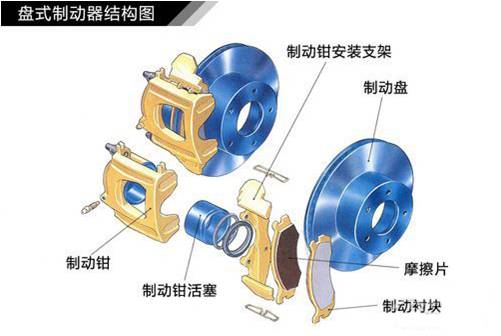

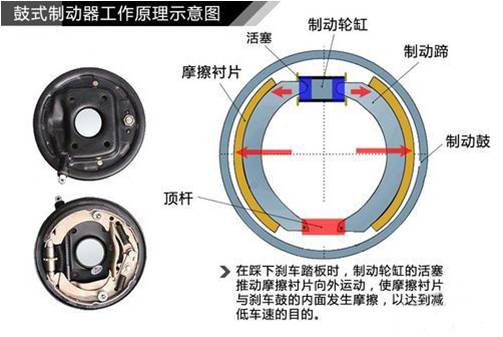

According to the type can be divided into: disc brake padand drum brake shoes

[1]Disc brake pads are generally used in small cars andcars

[2] drum brake shoes are mostly used by medium and largebuses, and the rear brake of a small number of cars is drum

According to the formula can be divided into: asbestosbrake pads, semi-metal brake pads, low metal brake pads, non-metal NAO brakepads, NAO ceramic brake pads

(asbestos formula brake pad has been basically eliminated,all kinds of formula have different performance focus, a good formula is thecore guarantee of excellent performance of brake pad.)

working principles

The way the brake pad ACTS as a brake is from friction,which USES the friction between the brake pad and the brake disc (or brakedrum) to convert the kinetic energy of the vehicle into frictional heat energy,making the car slow/stop

Disc brake pad under pressure clamps the rotating brakedisc to achieve braking effect

After the drum brake shoe receives the pressure, itsupports the rotating brake drum to achieve the braking effect

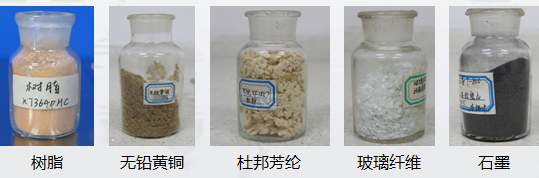

The function of various raw materials

• organic adhesives -- substrates that hold together avariety of raw materials, such as resins

• reinforcement fibers -- hold together powdered materialsto ensure their mechanical strength, such as metal or mineral fibers

• filling material -- filling volume, cost reduction,performance adjustment, such as barium sulfate

• rubbing materials -- provide friction and improve brakingability, such as corundum and metal oxide

• lubrication material -- stable friction coefficient,reduce braking noise, e.g. graphite

CHM series brake pads include Toyota. Honda. Mazda. Ford.Isuzu. Nissan and other series